For all businesses, inventory is a crucial part of the day-to-day and year-to-year operations. Without product to sell — or worse yet, parts or ingredients to make saleable items — a company cannot survive. Livestock agriculture is no different and, in fact, should be even more inventory-conscious than some sectors, as many of our feedstuffs are harvested once a year and are used over the course of 12 to 15 months. Thanks to modern technologies and transportation, we have made significant advancements in storing these perishable feeds.

Just as in other industries, agriculture-related businesses need to count, record and monitor their inventory throughout the year. Doing so multiple times throughout the year will protect your farm business from being short or long on feed inventory, which can be costly to replace. This is also a good time to check and monitor the quality of your grain and silages.

Specific to many livestock farms is the harvest and monitoring of forage inventory. Many livestock owners take their inventory for granted, as they tend to harvest the same amount of acres year after year for the same number of animals and hope they have enough feed to last them until the next growing season. However, growing seasons, yields and the number of animals tend to fluctuate, so feed and forage inventory should be conducted periodically (e.g., two or three times a year). There is no hard-and-fast “right” time to do an inventory audit, but here are a few common examples of when you might consider measuring your current forage and inventory:

- October—December: By now, harvest is complete. Identify the type, quality and tonnage of your new feedstuffs and determine where they might best be utilized in the coming months, as well as the level at which these forages can be fed in the ration to last until the next harvest season. At this point, you can start to budget your needs for any purchased feed. This is also a good time to label all of your forage inventory and the types of feed stored on the farm, if that has not already been done.

- February—March: Re-evaluating your forage inventory and monthly usage during this time ensures that your initial inventory and usage were accurate in the fall. Utilizing the silage density measurement (i.e., pound per cubic foot) is a well-known way to calculate inventory and will help ensure greater accuracy as you determine the total tons available going forward. Additionally, spring calculation can reveal any adjustments that might be necessary to avoid emergency feed purchases later.

- July—August: This is the last evaluation before the fall harvest — one last chance to adjust your harvest plans and really dial in on the feed intakes that will be required to get you through the harvest. Remember, corn silage starch is not completely available for digestion for two to four months after harvest, as fermentation is still working to break down these digestive barriers.

Time is always at a premium on the farm, so it can be hard to find time to account for the feeds you have on hand. As such, scheduling it on the calendar will help you make time and leaves one less task for you to try to remember amongst your many other duties. Taking inventory of forage can be daunting, but with a few resources, it is possible to accomplish. There is a different method for calculating the contents of the structure of each storage type. Silos are the oldest method of forage preservation, and many companies and universities have made the approximate capacities easy to determine in user-friendly charts like the one below.

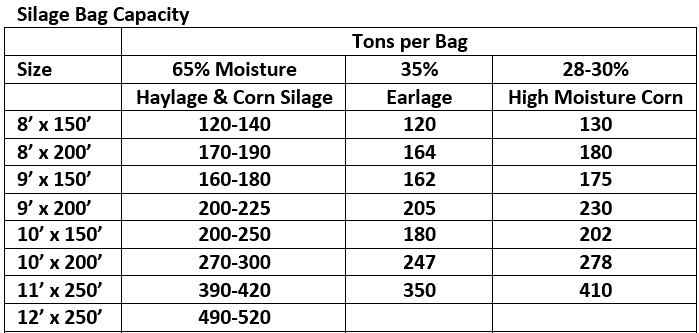

Silage bags have been increasing in popularity over the years and can be a great alternative to more permanent storage structures. Silage bags come in many different sizes and provide an excellent opportunity to maintain separation between hay crops, with easy identification. These silage bags can be placed anywhere and have a smaller feeding face, making harvest and feeding very flexible. Much like silos, forage bags are predictable, making it fairly simple to estimate the amount of feed they can hold. Charts for forage bags (like the ones below) estimate the capacities of each bag at a standard density, while many on-farm calculations will determine the approximate tonnage per foot and multiply that number by the length of the bag.

Forage stored in horizontal structures — like bags, bunkers and piles — have taken the place of vertical storage in many regions. The need for larger quantities of silages have led to the creation of large spans of concrete and asphalt that house mountainous piles of feed made to last beyond a year. Taking inventory of bunkers and piles requires the development of a series of rectangles and triangles to determine the cubic feet. The sidewalls on a bunker make calculations simpler than for a pile, which is not very symmetrical. Inventory, regardless of the storage unit, is very dependent on the density of the pack, and the density of the pack fluctuates depending on the type of crop, the moisture level and the height of the storage container.

To determine density, a known volume of feed must be removed and weighed. This is either done with a density probe or via forage removal from the face by using this equation:

(Square footage of the face) x (Depth of silage removed in feet) x (Dry matter weight of silage removed) = Dry matter density/ft³

The average density of silage piles and bunkers ranges from 13 to 16 pounds of DM/ft³. High-moisture corn and earlage piles will have a higher density, closer to 36 to 42 pounds of DM/ft³.

To determine the inventory in a bunker, calculate the cubic feet within the bunker core and bunker wedge:

Body length x Body height x Bunker width = Bunker core cubic volume

((Wedge length x Wedge height)/2) x Bunker width = Bunker wedge cubic volume

*If the bunker has two open ends, the bunker wedge cubic volume with be x2, wedge on each end.

(Bunker core cubic volume + Bunker wedge cubic volume) x DM/ft³ = Dry matter (tons) inside bunker.

Silage piles normally do not have straight sides or ends, so compared to other storage methods, piles are the most difficult to measure when calculating inventory. With wedges on all sides of the pile, many triangles and rectangles would have to be used to calculate the cubic feet in the pile — and the larger the pile, the harder it is to measure. Very few farms still utilize this method to calculate inventories for a pile of any size because of the variances that result from their imperfect shape.

Fortunately, much like the charts created to help with calculations for silos and forage bags, desktop calculators and apps have been created to help farms and nutritionists determine the forage inventories of bunkers and piles. Within the last three years, many silage piles and bunkers have begun being measured with drones. These micro aircrafts take thousands of pictures, which are uploaded into a software program that processes the pictures into dimensions, giving us the cubic volume. The operator then inputs the average density and moisture level, allowing the program to calculate the as-fed and dry matter tonnage left in storage. This can be a tremendous tool, providing us with very accurate data in a short amount of time.

Even with this new technology, however, knowing the average density of the pack is essential. Although taking core samples can be an accurate way to measure the density within a pile, multiple samples must be taken to ensure accuracy. Since accessing the silage face is very dangerous, we recommend that farms remove the whole silage pile face to a specific number of inches, weigh it, and then calculate the density, allowing for a safer and more accurate density calculation.

Gone are the days where most of us could count a few hundred bales and measure a silo for a simple feed inventory. Although it may seem like an insurmountable task, calculators and new technologies can make taking inventory easier than ever before, ensuring that you can manage your forage inventory and minimize forage shortages as you head into spring. Find a schedule that works for you — and put it on the calendar to remind yourself to take measurements two or three times a year. Contact your local Hubbard representative to help you conduct a forage inventory before the snow piles up.

- Log in to post comments